HOW IS THE Ludwig Reiter TRAINER MADE?

What once started as a military sports shoe has evolved into an iconic, ultra-comfortable sneaker that gained its fashion-forward momentum in the 1990s, thanks to Helmut Lang. Today, it remains highly popular and is even considered a collector's item in many circles.

Discover in detail how the iconic Ludwig Reiter Trainer is handcrafted.

QUALITY CONTROL

Ludwig Reiter sources leather and raw materials from Italy, France, and Germany. Some special types of leather, such as bison leather or specific types of horse leather, are sourced from America due to their superior quality. Each of our raw materials is subject to specific European standards that guarantee quality. The leather is carefully inspected for small natural imperfections (e.g., wrinkles, cracks, mosquito bites) and marked accordingly, so these can be considered during the cutting process.

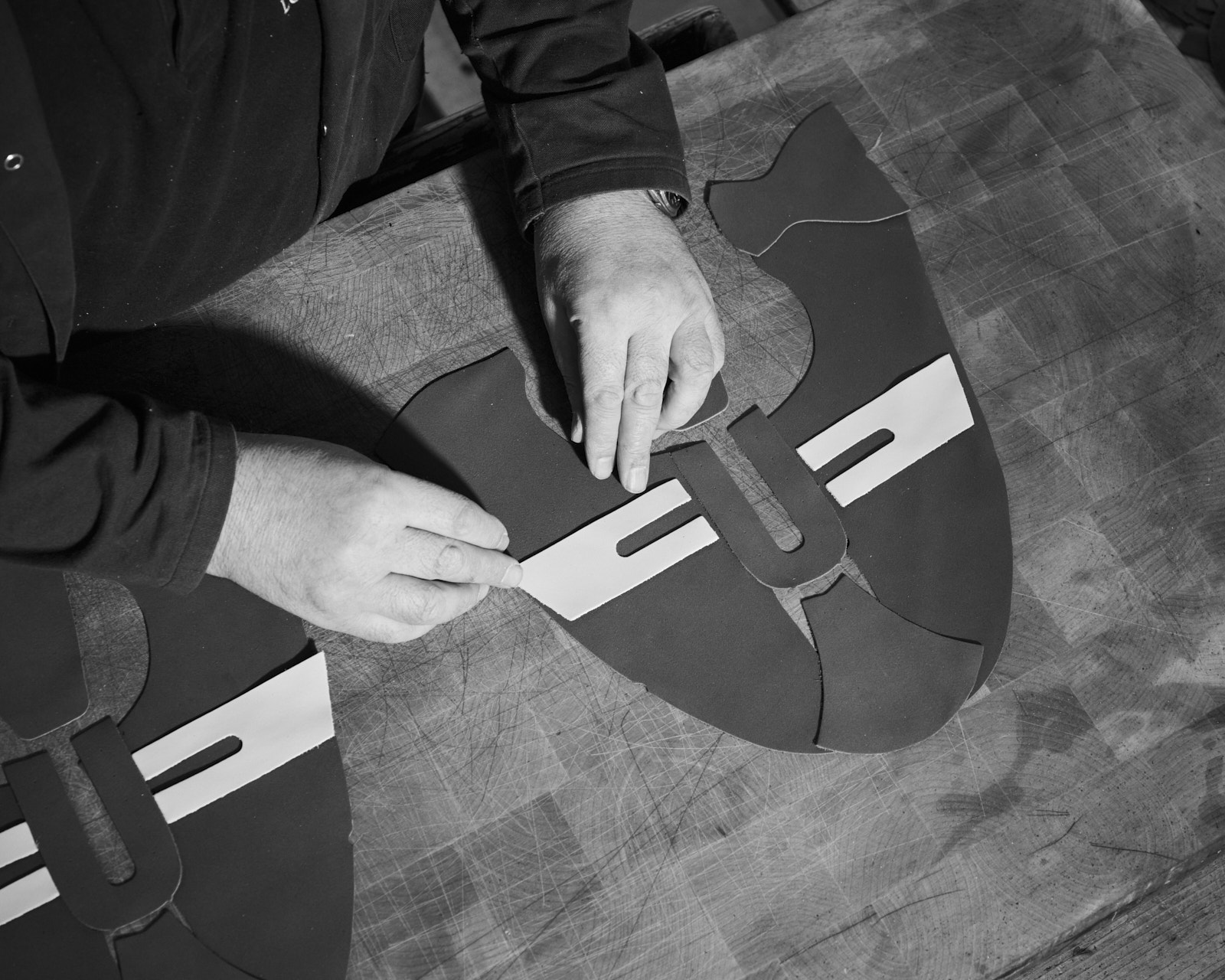

THE CUTTING PROCESS

The individual elements of the upper part—such as the front and back flaps, side panels, leather lining, etc.—are cut by hand using a template and a knife or punched out with a die-cutting tool. This step requires extensive experience with the material and is performed only by our most skilled employees.

ASSEMBLY

The individual parts of the upper leather are assembled by hand and prepared for stitching. A particularly smooth marble stone is used during this process to ensure the leather does not get scratched.

STITCHING THE UPPER PART

Stitching the upper part involves sewing together the elements of the upper and the lining in many individual steps. Each stitch must be precise; if a stitch goes off course, the process often has to start over from the beginning.

THE LINING LEATHER

In this step, the upper leather is combined with the leather lining, a process known as 'lining,' and then stitched together. The leather lining plays a significant role, as it is as important for the "shoe climate" as the upper leather. It must absorb a substantial amount of the foot's moisture.

PINICHING

The upper and lining leather are now stitched together, and the shoe has reached the assembly stage, where it will be connected to the sole in several steps. To give the shoe its characteristic shape, the last must be inserted.The last remains in the shoe until it is fully completed.

SPORT SOLE

The high-quality sport sole is now glued in place. Its non-slip texture ensures stability and turns every step into a comfortable experience. Perfect for everyday wear.

FINALISATION

In the final steps of production, the insole is carefully inserted. Finally, the shoelaces are threaded, and the shoes are prepared for use.

Finish

At the end of the process, our trainers undergo a thorough quality check to ensure that each pair meets our high standards. They are then packed into sustainable shoe boxes. These boxes are not only environmentally friendly but also perfect for storing your favorite shoes.